Hooked on Solar (HoS) is a family-owned solar energy company located in Northern California. They’ve completed over 6,500 solar panel and battery installations at single-family homes, factories, and apartment buildings.

During their busiest times HoS manage hundreds of installations per month. About 35 team members access their inventory, and according to Vice President Roger Stephens, their parts warehouse was “a complete mess.”

Hooked on Solar has 23,000 products in inventory, so Stephens knew something had to change.

Trying to find the right inventory system

When Stephens joined the company he first tried a leading cloud inventory program. Although that solution helped, Stephens identified a serious gap in how it handled stock levels.

If the stock levels in the software were incorrect, HoS technicians would have to “fake” a purchase order before they could take parts out of inventory. And they’d often have to do this from inside a van parked at the jobsite. These faked transactions needed to be corrected back at the warehouse, costing them more time and introducing the potential for errors.

On top of that critical workflow issue, Stephens realized that the parts team was also storing inventory items on six separate web-enabled spreadsheets. This made it much more difficult to get a complete picture of their inventory in one place.

In a previous role Stephens had actually written a custom inventory management program himself, and he was beginning to wonder if he’d have to do that again.

What sets inFlow apart from the competition

Then Stephens found inFlow while searching for inventory management solutions. What impressed him was inFlow Inventory’s simplicity and user-friendliness.

Stephens said, “I’ve looked at nearly 30 different inventory packages. When I got started with [inFlow Inventory] I thought, what the heck? This is super-easy. The first guy who went out and put 25 items in inFlow, I only spent two or three minutes training him.”

inFlow’s ease of use made it easy to train staff members on how to put-away, pick, and count inventory items, increasing the team’s efficiency.

Outcome

Stephens rolled out inFlow Inventory at HoS and rapidly saw the benefits.

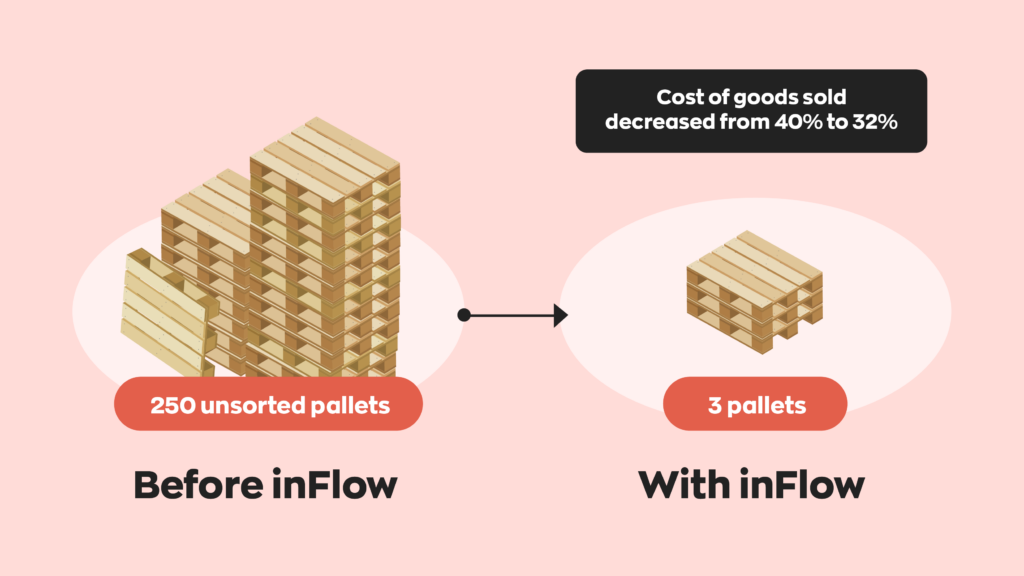

Before adopting inFlow Inventory, HoS had about 250 pallets sitting unsorted on the warehouse floor. With inFlow that problematic inventory is down to just three pallets.

Stephens finds inFlow’s powerful sorting and filtering features helpful to rapidly locate items, searching multiple fields for one keyword. “When you get organized, you can find stuff a lot better,” Stephens said.

Since the rollout of inFlow inventory started, HoS’ installation teams are more efficient. The installers can check an inventory report and be confident that the parts listed in inFlow are actually in the van, ready to install. “In other words, they don’t have to run to the store as much,” Stephens said. “They don’t have to go to the supply houses as much. That all costs money.”

The combination of more accurate stock reports and an easy-to-use interface have started to generate ongoing savings for HoS. “I was able to take our cost of goods from 40% down to 32%,” Stephens said. Those savings add up quickly when you recall that they have 23,000 products to track.

0 Comments